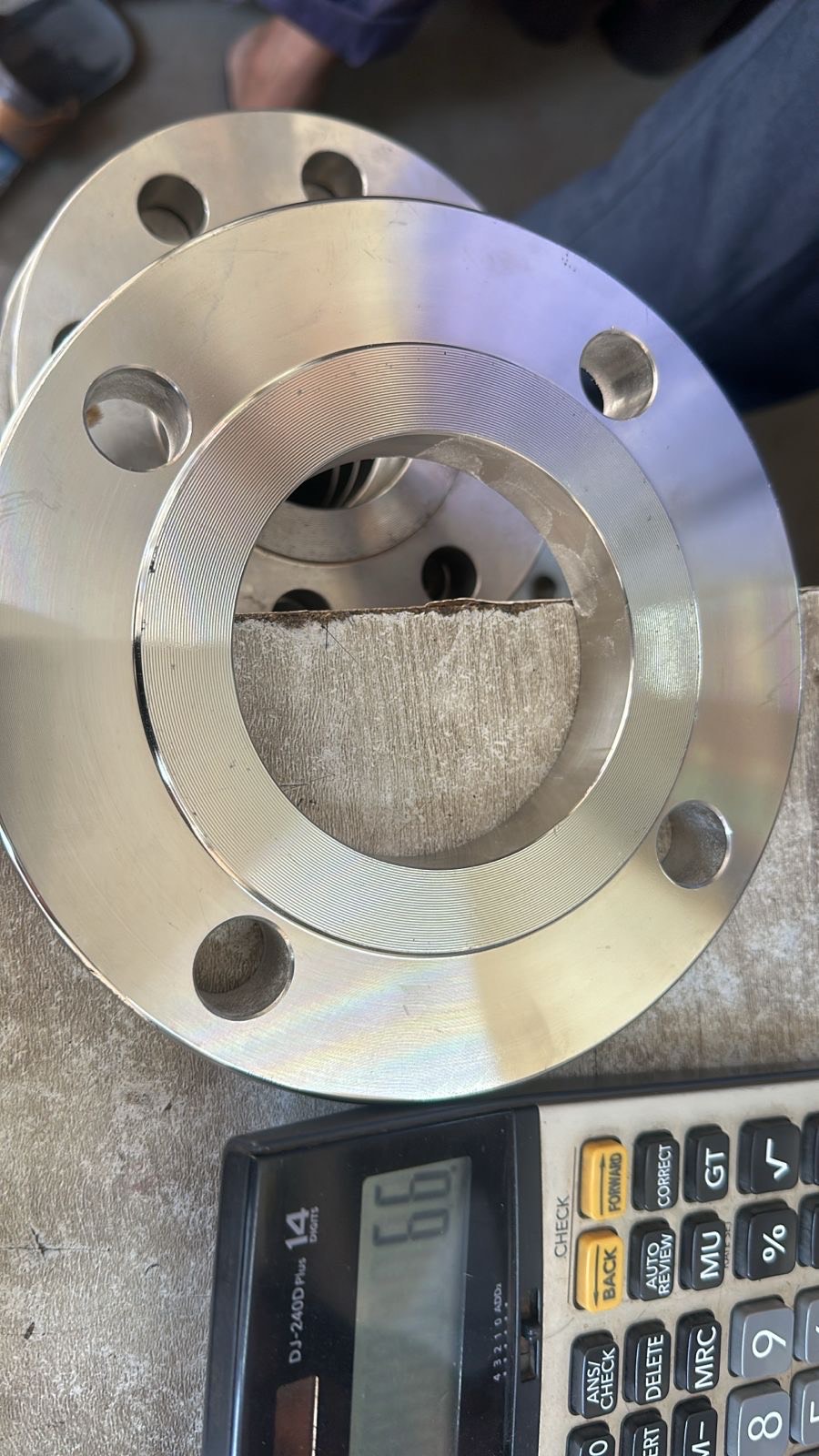

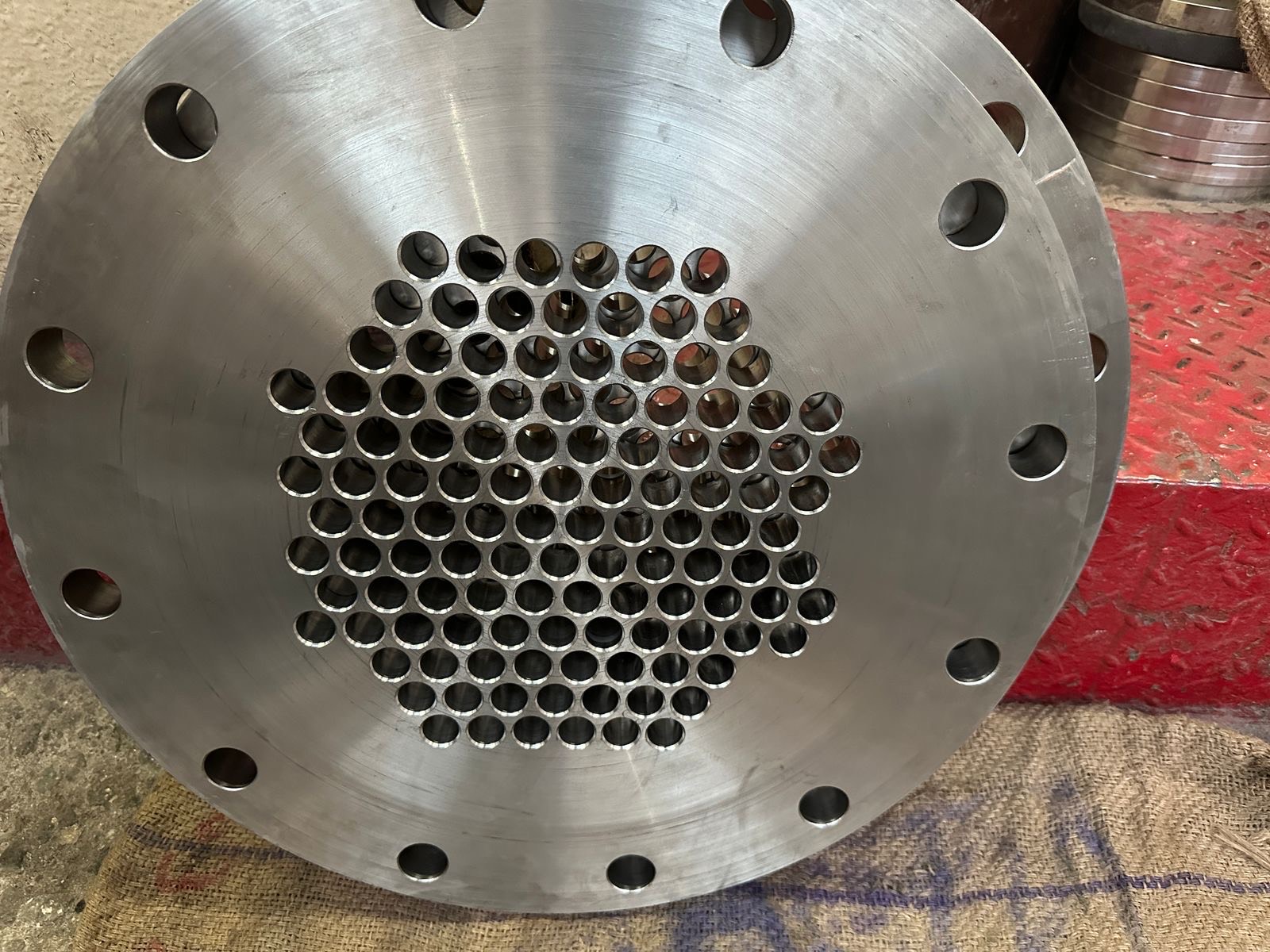

Our range of industrial flanges are ideal for application in diverse industry for high pressure and temperature applications. These flanges are designed with precision for easy installation. Apart from standard flanges, we also offer custom designed flanges to meet the specific application requirements of the customers.

| Material | Grades / Details |

|---|---|

| Stainless Steel | ASTM A479, A182 - 202, 304, 316, 321, 409, 410, 420, 431 |

| Duplex & Super Duplex | F44, F45, F51, F53, F55, F60, F61 |

| Carbon Steel | ASTM A105, A350 LF2, A106 Gr A, B, C, A333 Gr 6, 3 |

| Alloy Steel | ASTM A182 EN19, EN24, EN36, 4140, F11, F22 |

| Tool Steel | H11, H13 |

| Die Steel | D2, D3 |

| Nickel Alloys |

Nickel 200 (UNS N02200), Nickel 201 (UNS N02201), Monel 400 (UNS N04400), Monel 500 (UNS N05500), Inconel 800 (UNS N08800), Inconel 825 (UNS N08825), Inconel 600 (UNS N06600), Inconel 625 (UNS N06625), Inconel 601 (UNS N06601), Hastelloy C276 (UNS N10276), Alloy 20 (UNS N08020) |

| Copper Alloy Steel |

C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30), UNS C10100, C10200, C10300, C10800, C12000, C12200 |